ACBWOOD

We make kitchen worktops, bars, table tops of all kinds, living room furniture, hall cabinets and bathroom furniture. We work continuously with Oak, Tali, Iroko, ash wood and Saman walnut.

LARGE SIZE FORMAT FOR VERY VIP CUSTOMERS.

Acb WOOD manufactures furniture with exclusive solid tops and doors due to their size and treatment.

It is so difficult to get planks up to 400cms long and up to 130cms wide to make one-piece tables, without a joint, thus showing the enormous beauty of a whole trunk of wood. It is as difficult to achieve those sizes, as working and drying that wood so that it does not produce movements, cracks and twists with such a volume of board. It seems impossible, but WE DO IT… We invite you to look for these sizes in the commented woods, and in a single piece so that you can be convinced of the exclusive and beautiful product that you can purchase.

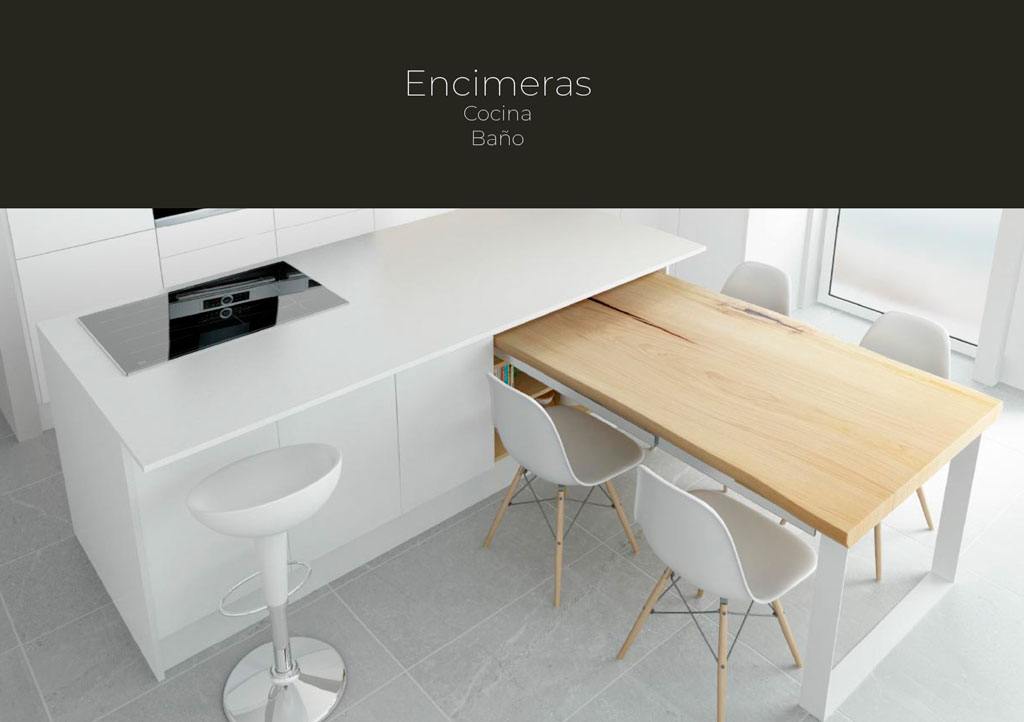

WORKTOPS

European oak

Grain, sapwood and colour: Yellowish brown and brown with light yellow, Density at 12% humidity: 0.77Kgm / 3. Semi-heavy wood.

Hardness: 5.8. Hardwood.

Dimensional stability coefficient: 0.48%.

Tali

Grain, sapwood and colour: Yellowish brown that goes to reddish brown and yellowish white

to pinkish white.

Density at 12% humidity: 0.92kgm / 3. Very heavy wood. Hardness: 8.5. Very hard wood.

Dimensional stability coefficient: 0.52%.

Iroko

Grain, sapwood and colour: Brown yellowish turning to reddish brown and yellowish white. Density at 12% humidity: 0.65m / 3. Semi-heavy wood. Hardness: 3.9. Hardwood. Stability coefficient dimensional: 0.36%. tability coefficient dimensional: 0.36%.

European Ash tree

Grain, sapwood and colour: Pinkish white and yellowish white. Density at 12% humidity: 0.69Kg / m3 semi-heavy wood. Hardness: 4.2 semi-hard wood. Dimensional stability coefficient: 0.45%.

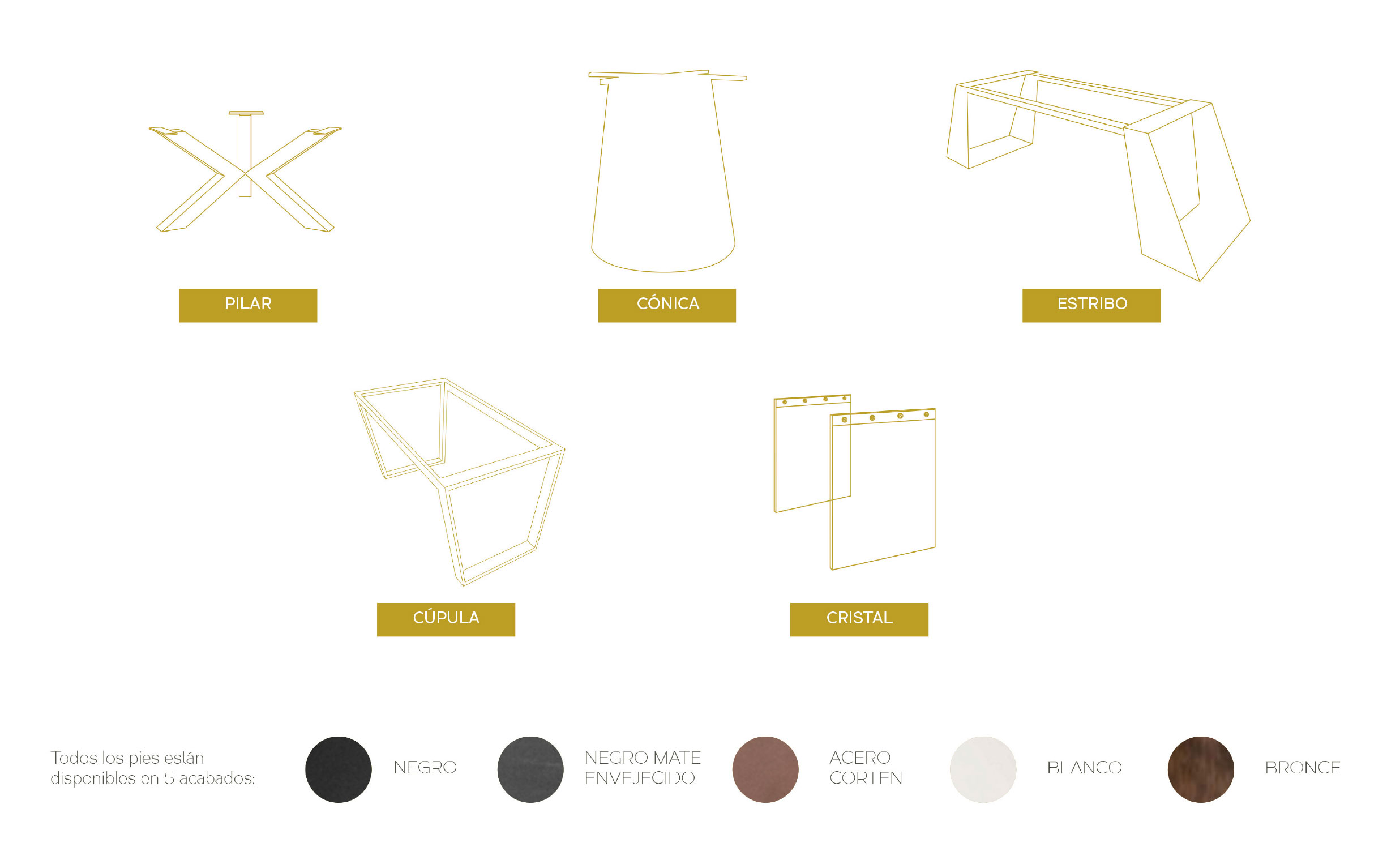

PEDESTALS

MANUFACTURING PROCESS

CRAFTSMANSHIP TREATMENT WITH THE LATEST TECHNOLOGY

For this we select the best tree trunks classified by quality and size at source, we bring them here and we saw them and dry based on the needs of our clients, thus being able to work totally “à la carte”. Careful drying and stabilization of this wood is essential and requires the classification of expert carpenters and the latest drying technology, as well as numerical control machinery that works to guarantee its firmness for life …

ECOLOGY AND CULTURE OF WOOD

Forests are important carbon reserves, the main gas causing the greenhouse effect and climate change. Trees take CO2 from the atmosphere during their photosynthesis process and fix it inside them throughout their growth. By cutting down a tree and replacing others, the former is transformed into a wood product without losing the carbon inside, and when replanting other trees, we follow the process of collecting CO2 for the new ones. This is the great importance of sustainable forests, and the importance of forest regeneration to alleviate climate change, since 1m3 of wood takes around a ton of CO2. In addition, its transformation requires less energy than any other construction product and even its waste is 100% biodegradable and eternally recyclable.

Respect for the environment is for acbwood an inalienable principle, defending the consumption of wood as an ecological and environmental good, subject to responsible and sustainable control by the competent authorities. All the woods used by acbwood comply with the applicable legislation in international trade both in Spain and in the countries of origin.